Download User Manual

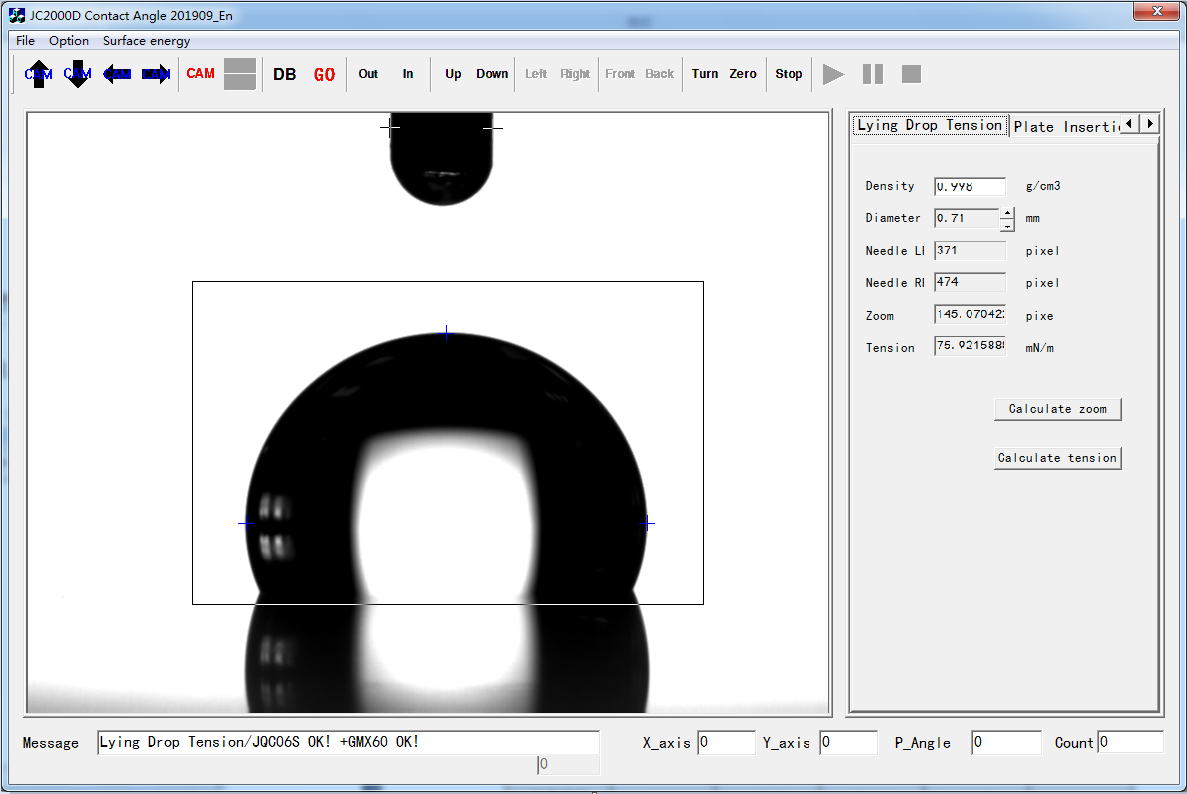

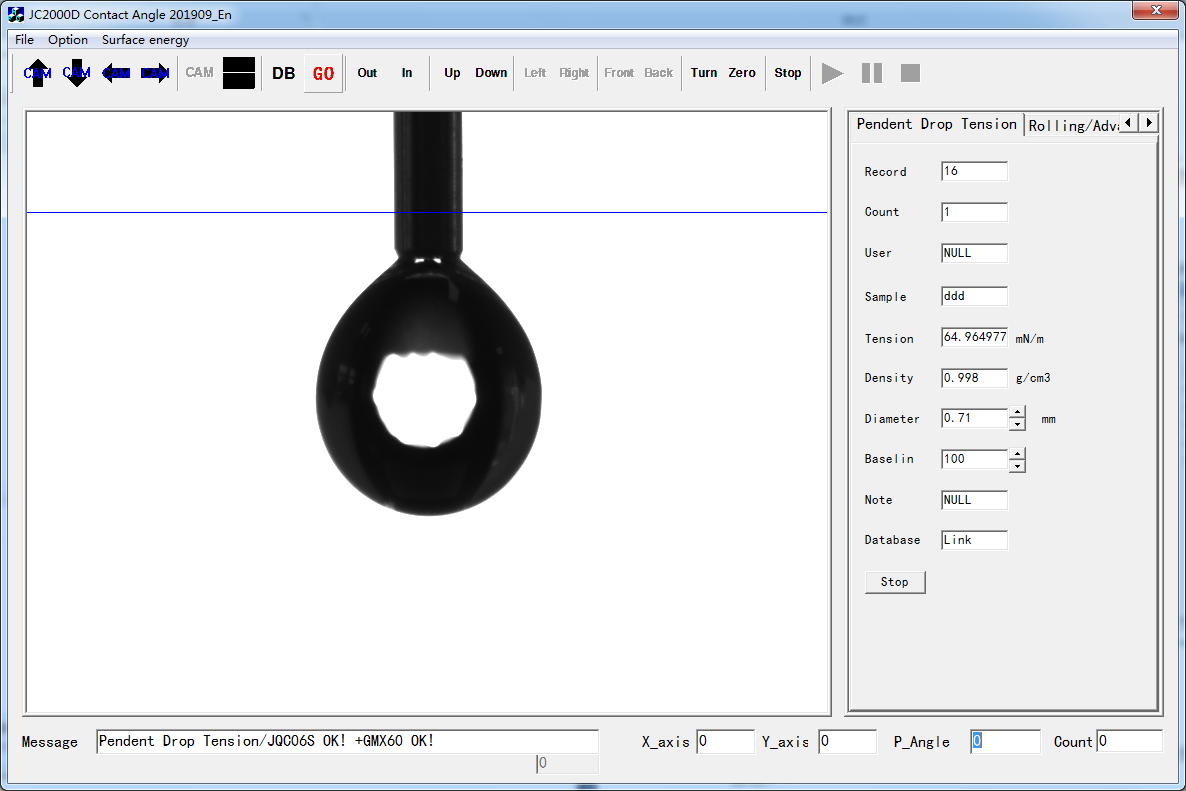

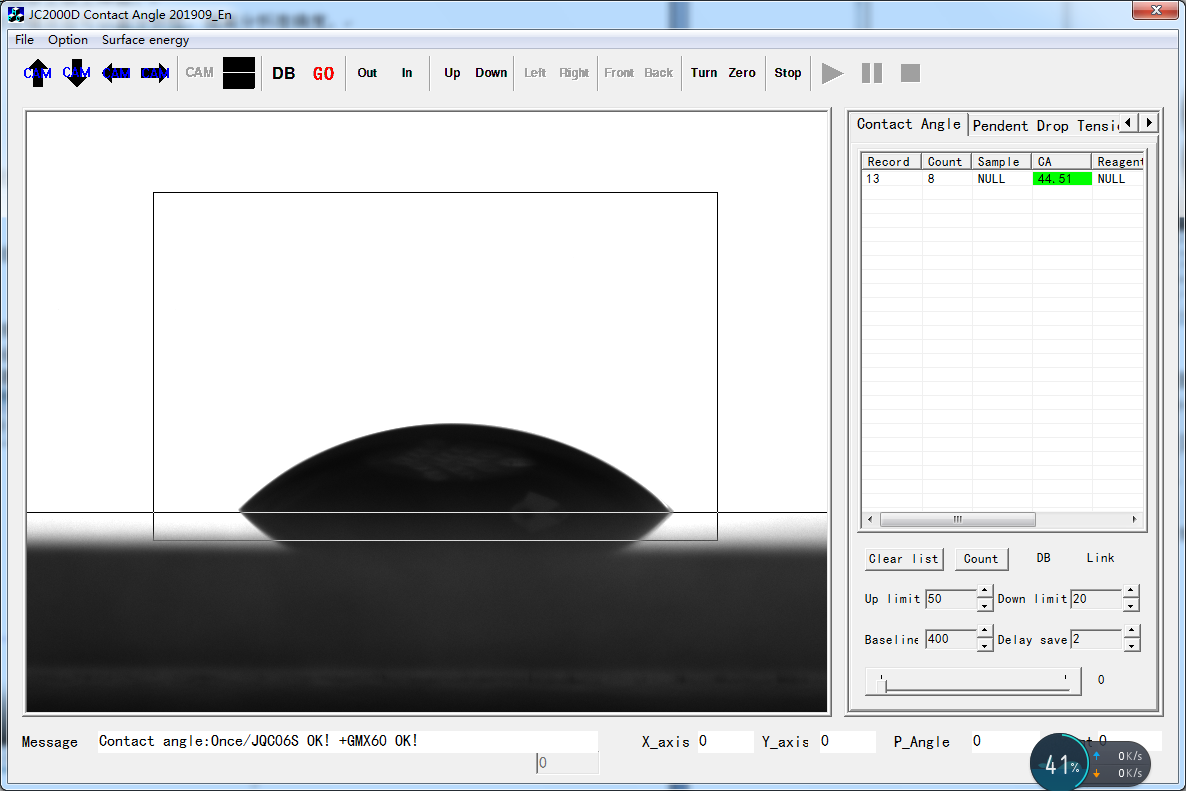

The JC2000D1 contact angle meter is mainly used to measure the contact angle of a liquid on a solid, i.e., the wettability of a liquid on a solid. It can also measure the contact angle when the external phase is liquid. This instrument can measure the contact angle of various liquids on various materials, such as bulk materials, fibrous materials, and textile materials. Powder samples can also be measured after tableting. This series of instruments can also measure and calculate surface/interfacial tension, CMC, droplet shape and size, surface free energy, advancing angle, receding angle, and roll-off angle.

The difference between JC2000C and JC2000D

The JC2000C was introduced more than 10 years ago, renowned for its stability. Its accuracy and major parameters are similar to the current JC2000D series. It is a budget choice for the excellent performance. Due to structural limitations, it cannot be expanded as JC2000D.

The JC2000D series offers a variety of expansion options, which can be implemented both before and after the sale. This feature saves the users cost and time when they divert their research direction or have new products in their production line.

JC2000D1 Contact Angle Meter Standard Components

- USB Industrial Camera (1 unit)

- Continuous Zoom Optical System (1 unit)

- Manual Rotary Knob-Type Sample Dosing System (1 unit)

- Manual Industrial Camera Tilt Platform (1 unit)

- Image Analysis and Measurement System Application Software (1 unit)

- User Manual (1 soft copy)

- 50 μL Micro-syringe (1 unit)

- 100 μL Micro-syringe (1 unit)

- Disposable syringe tips (2 units)

JC2000D1 Contact Angle Meter specification

- Contact Angle Measurement Range: 0~180 degrees

- Contact Angle Measurement Resolution: 0.01 degrees

- Surface Tension Measurement Range (Pendant Drop Method): 0.01~2000 mN/m

- Sample Stage Adjustment

- X: Manual, travel 50mm, accuracy 0.1mm

- Y: Manual, travel 50mm, accuracy 0.1mm

- Z: Manual, travel 45mm

- Leveling Adjustment: Leveling feet adjust the platform level

- Sample Stage Dimensions: 70mm×100mm, Sample Dimensions (Length×Width×Height) ≤100mm×∞×25mm

- Sample Temperature: Room temperature; various cooling/heating temperature control components can be selected before/after sales

- Injector Control

- Z Movement components: manual, rack and pinion, 25mm travel, 0.1mm accuracy

- Manually Rotary Knob-Type syringe

- Industrial camera optical system

- Continuous zoom Objective lens 0.7~4.5× + eye piece, Image magnification: greater than 70~420 pixels/mm

- Standard USB-based digital industrial camera (optional industrial cameras with higher frame rates and higher transmission speed, see Optional Components.

- Industrial camera control

- Light source: Adjustable LED monochromatic cold light source

- Lens X-Y adjustment: Manual, 10mm travel, 0.1mm accuracy

- Lens tilting adjustment: Manual tilt platform

- POWEREACH® V2.11 image acquisition and analysis software

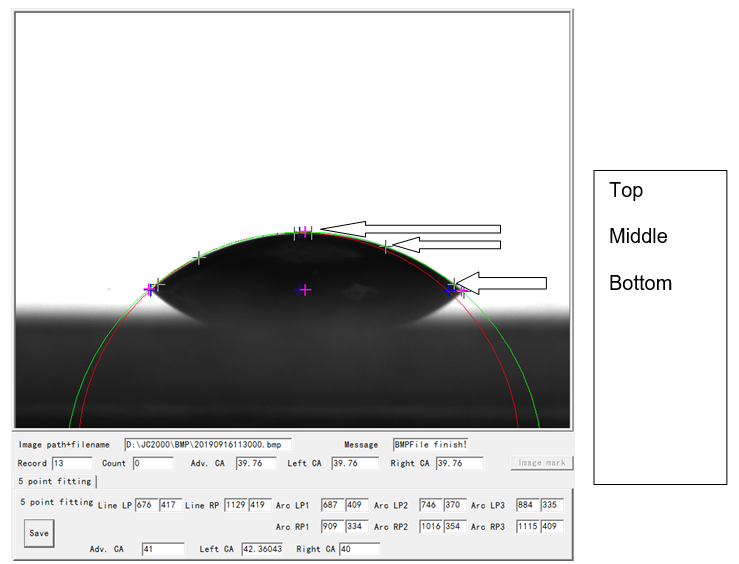

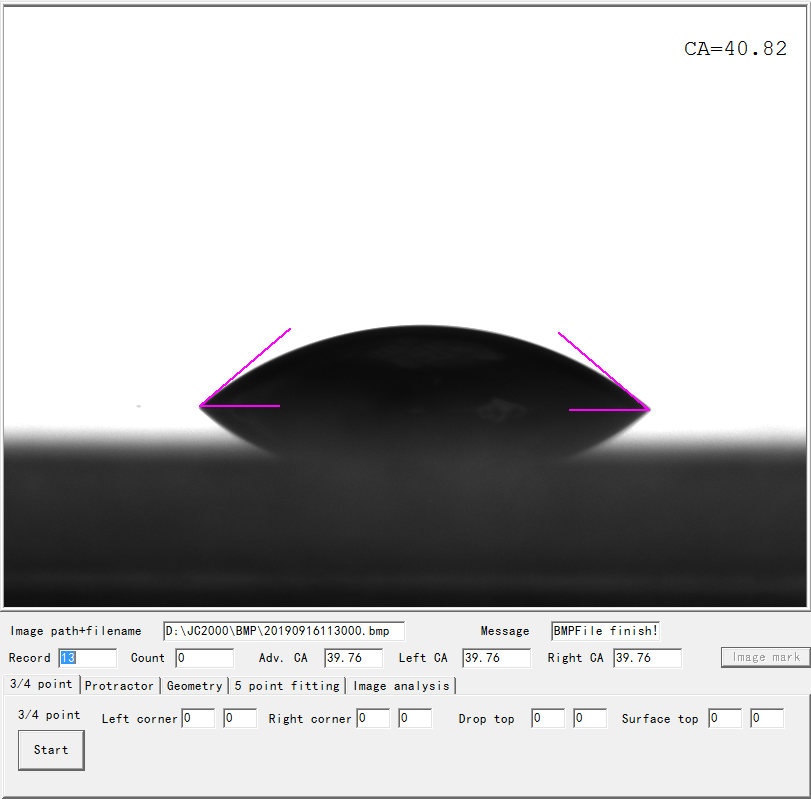

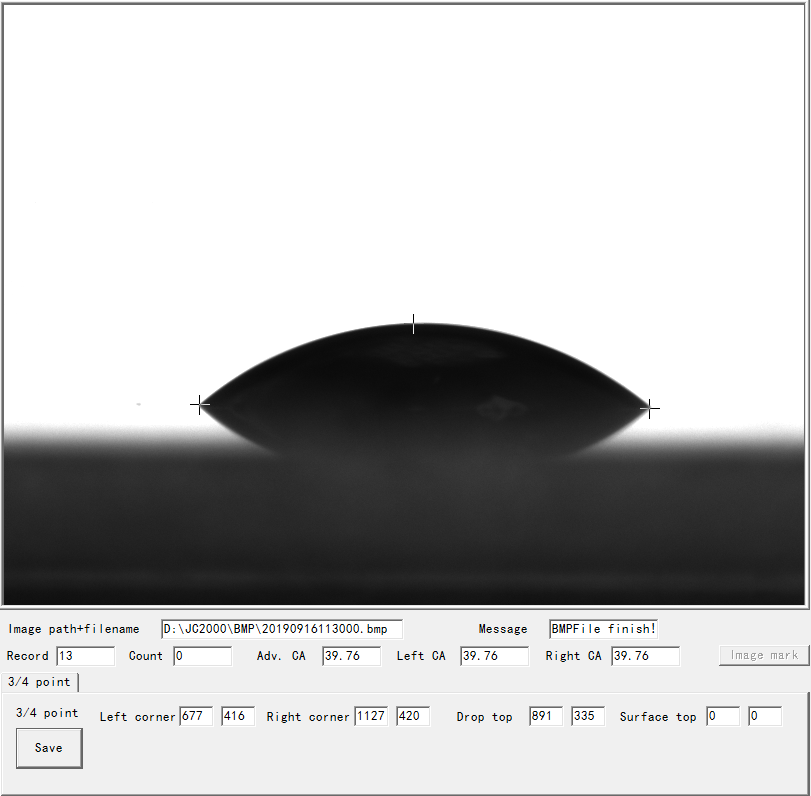

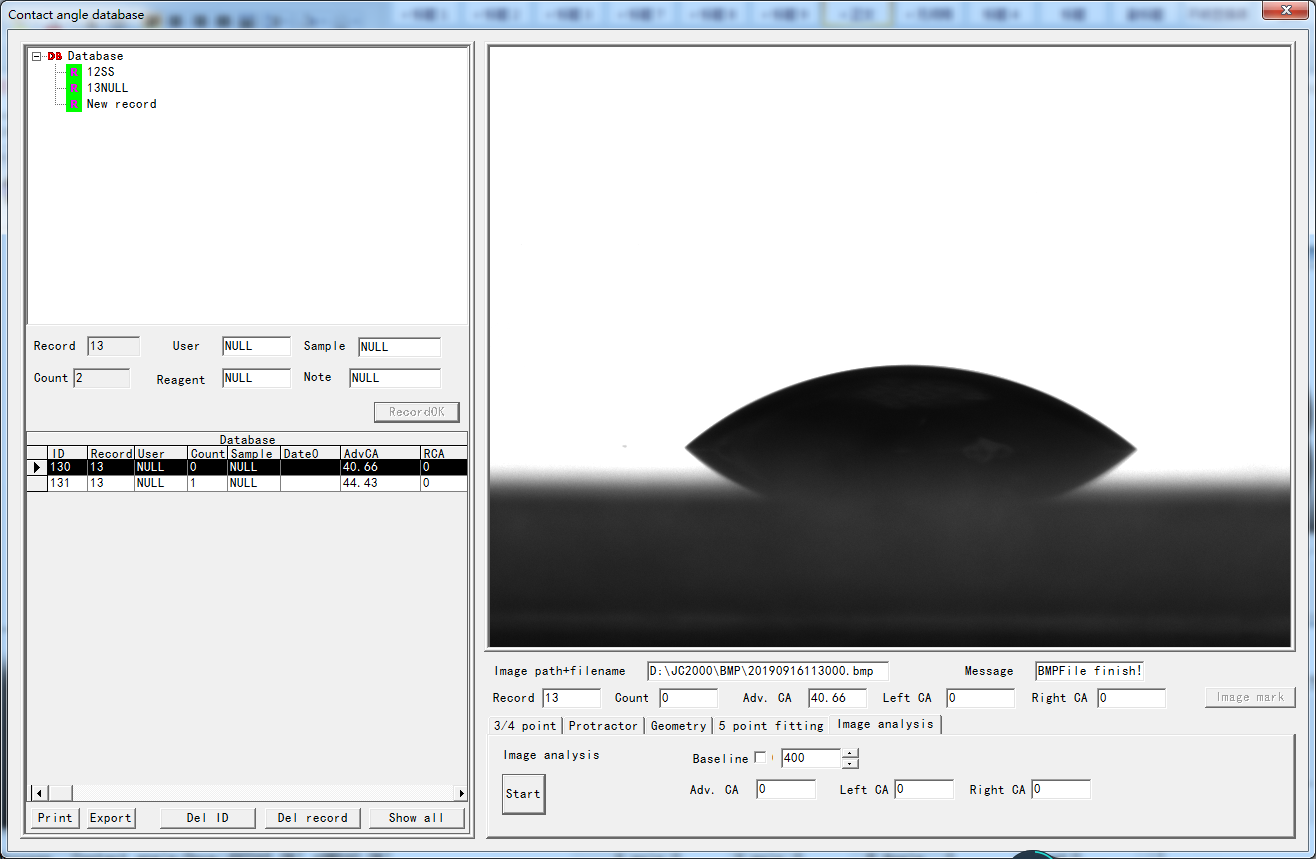

- Measurement methods: Half-angle angle measurement, half-angle height measurement, automatic measurement method (circle fitting, ellipse fitting, Young-Laplace), five-point fitting method

- Dynamic video measurement

- Storage Interval: Software-defined interval time 1-3600 seconds

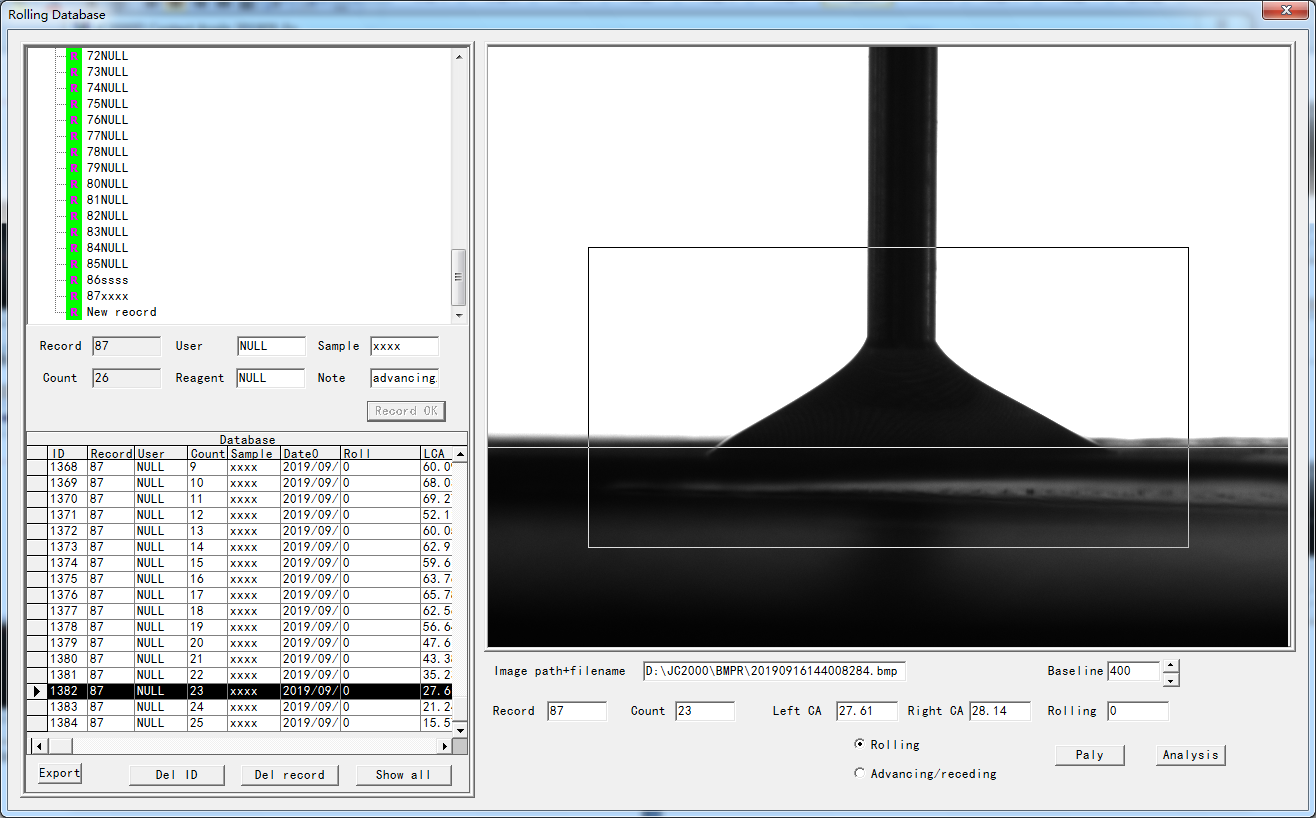

- Dynamic contact angle: Advancing and Receding angles; for Roll-off angle measurement, a rotation platform or overall rotation mechanism should be ordered.

- Left and right angles comparison: Calculates left and right angles and takes the average value.

- Droplet volume control: Software control, accuracy ≤0.1 μL (requires a fully automatic precision syringe).

- Surface free energy: Zisman method, EOS equilibrium method, Owens two-liquid method, Wu two-liquid method, Lewis acid-base three-liquid method, and other methods are available.

- Curved Surface Correction: Measurement of contact angle on concave and convex surfaces.

- Software upgrade: Lifetime free upgrades.

- The instrument’s overall structure has 7 degrees of freedom for adjustment. The equipment’s dimensions are 510mm x 300mm x 440mm, and its net weight is 12kg.

- Modular design and expandability: Whether is before sales or after sales, the JC2000D series can be continuously expanded with application components without replacing the machine.

JC2000D series Contact Angle Meter Optional components

- JC2000D series Contact Angle Meter standard model (JC2000D1)

- Fully automatic precision syringe (software control, accuracy 0.1 μL, 7 nL/step, including control box)

- Optional cameras

① Optional: USB 3.0 Daheng digital industrial camera (MER-031-860U3M), monochrome, 310,000 pixels, 860 frames/second

② Optional: USB 3.0 Daheng digital industrial camera (MER-302-56U3M), monochrome, 3.02 million pixels, 56 frames/second

③ Optional: USB 3.0 Daheng Digital Industrial Camera (MER-502-79U3M), monochrome, 5.02 million pixels, 79 frames/second

④ Optional: USB 3.0 Daheng Digital Industrial Camera (MER-503-36U3M), monochrome, 5.03 million pixels, 36 frames/second

⑤ Optional: USB 3.0 Daheng Digital Industrial Camera (MER-131-210u3m), monochrome, 1.31 million pixels, 210 frames/second

⑥ Optional: USB 3.0 Daheng digital industrial camera (MER-131-210U3M NIR), 1.31 million pixels, 210 frames/second, infrared enhanced industrial camera

- High-precision automatic sample dosing pump (software controlled, accuracy 0.01 µL, 7 nL/step, cannot be selected simultaneously with item 2)

- Manual 360-degree horizontal rotation sample platform

- Manual sample tilt platform (±15 degrees)

- * Integrated rotation mechanism

- * Manual/Automatic Integrated Rotation Mechanism (excluding control box)

- Electromechanical Control Box

- Temperature Control Platform Modules:

- Controllable heating platform room temperature ~200℃

- Controllable heating platform room temperature ~400℃

- Controllable heating syringe, room temperature ~200℃

- Controllable heating syringe, room temperature ~300℃

- Temperature control platform using Ultra Thermostat, -5~95℃

- Temperature control platform using Ultra Thermostat, -20~95℃

- Temperature control platform using Ultra Thermostat, -65~95℃

- Liquid-Liquid-Solid Contact Angle Measurement Cell, Bubble Capture Method Kit

- Plate Insertion Method Accessories

- Electric X, Y Platform

- Fully Electric 3D Platform (X, Y Platform and Focusing)

- Advanced Zoom Optical System, Continuous Zoom)

- Optional 50ul/100ul micro syringe, Disposable micro syringe, Superhydrophobic Syringe and Fixture

- Fabric Stretcher

- Fiber Measurement Special Stand

- Peristaltic Pump (second dosing device)

- Image Analysis Automatic Contact Angle Measurement Software: Free

- HY-12 Infrared Tablet Press (Including Easy-Release Mold)

- HY-12 Infrared Tablet Press (Including Easy-Release Mold and Vacuum Pump)

- Optical Angle Scale Calibration Tool Without Third-Party Calibration Report

- Optical Angle Scale Calibration Tool with Third-Party Testing Report

* Note: The temperature control platform (item 10) and the rotation/tilt platform (item 5 or 6) can be used interchangeably, but they cannot work simultaneously. If the user wants to measure the roll-off angle while controlling the temperature, or finds the interchange inconvenient, the integrated rotation mechanism (item 7 or 8) should be selected instead of the rotation platform (item 5 or 6).

Please contact us for technical consultation and a quote.